Special Projects and Installations

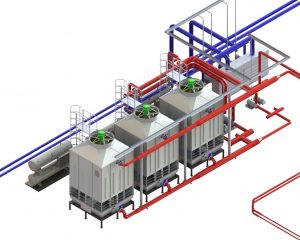

With extensive technical know-how, Körper is equipped to handle the most complex heat exchange projects across virtually all market segments. The design and execution of projects are based on the specific needs of each client, considering three fundamental aspects: the physical characteristics of the location, the layout of the production process, and the best cost/benefit ratio.

Each step of the technical assessment is closely monitored by our technical team, from the initial data collection to equipment sizing, flowchart creation, isometrics, calculation memorials, and final detailing. Among the various materials available for piping (carbon steel, stainless steel, PVC, polypropylene, copper, etc.), the one with the most appropriate characteristics for the heat exchange process is selected. This same criterion is applied when selecting instruments and controls, ensuring maximum quality and total reliability in the process.

Additionally, Körper’s hydraulic installation projects adhere to the latest standards, following procedures recommended by various regulatory bodies such as ASME, TEMA, and ABNT.